A partner you can trust

What is the Importance of Wire Cable in Modern Electrical Systems

In today's fast-paced technological landscape, the significance of wire cable in modern electrical systems cannot be overstated. As per the latest data from the International Wire and Cable Manufacturers Association, the global wire and cable market is projected to reach a staggering $200 billion by 2025, highlighting the indispensable role these components play in various industries, from telecommunications to renewable energy.

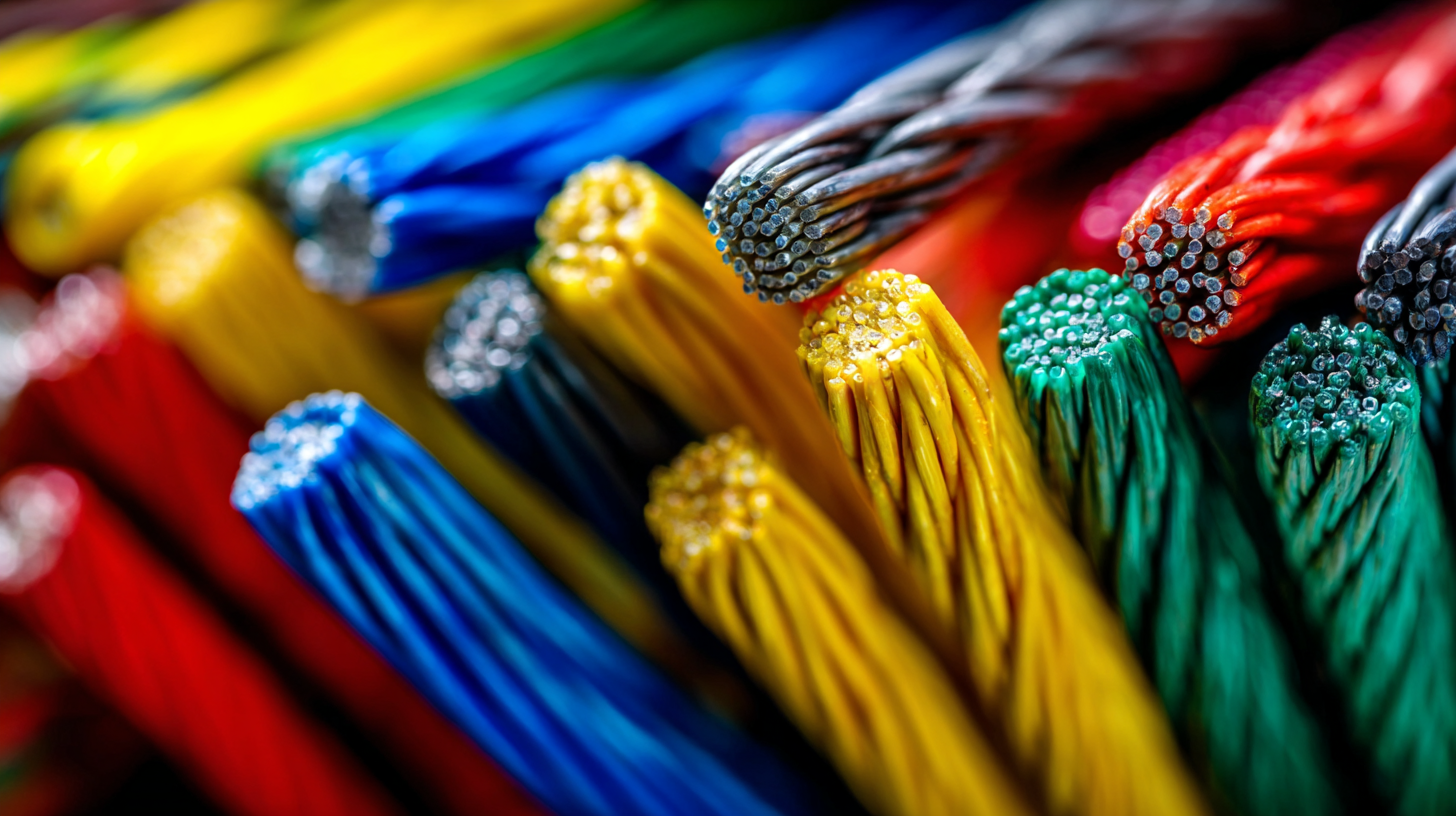

Wire cables serve as the backbone of electrical infrastructure, ensuring efficient power transmission and data communication. Their ability to conduct electricity and provide connectivity is crucial in an era that demands high-performance, reliable systems.

Moreover, advancements in wire cable materials and technologies are continuously enhancing their performance and safety, thereby meeting the evolving demands of modern applications.

Understanding the importance of wire cable is essential for professionals in the electrical engineering field, as it directly impacts the efficiency and sustainability of electrical systems.

Wire cables serve as the backbone of electrical infrastructure, ensuring efficient power transmission and data communication. Their ability to conduct electricity and provide connectivity is crucial in an era that demands high-performance, reliable systems.

Moreover, advancements in wire cable materials and technologies are continuously enhancing their performance and safety, thereby meeting the evolving demands of modern applications.

Understanding the importance of wire cable is essential for professionals in the electrical engineering field, as it directly impacts the efficiency and sustainability of electrical systems.

The Role of Wire Cables in Ensuring Electrical Safety Standards

Wire cables play a critical role in modern electrical systems, especially when it comes to ensuring electrical safety standards. As highlighted in the 2023 National Electrical Safety Code, which has been a cornerstone for electric and telecom utility industries since 1914, proper wire and cable usage is paramount for minimizing hazards and ensuring reliable operations. With the electrical conduit market projected to reach USD 1.72 billion in 2024 and growing at a CAGR of 4.17%, the demand for high-quality wire cable that complies with safety regulations continues to rise.

Moreover, the market for cold shrink cable accessories is also experiencing significant growth, estimated to reach USD 3.82 billion by 2034, riding on a robust CAGR of 9.80%. This indicates a shift toward advanced technologies in wire cable installations, which enhance safety and performance. As professionals like Randy Barnett emphasize, understanding the standards for medium-voltage conductors and cables is essential for electricians to ensure compliance and protect infrastructure from electrical failures. Ensuring that all components meet stringent safety requirements not only safeguards equipment but also protects lives in both residential and industrial settings.

Importance of Wire Cable in Modern Electrical Systems

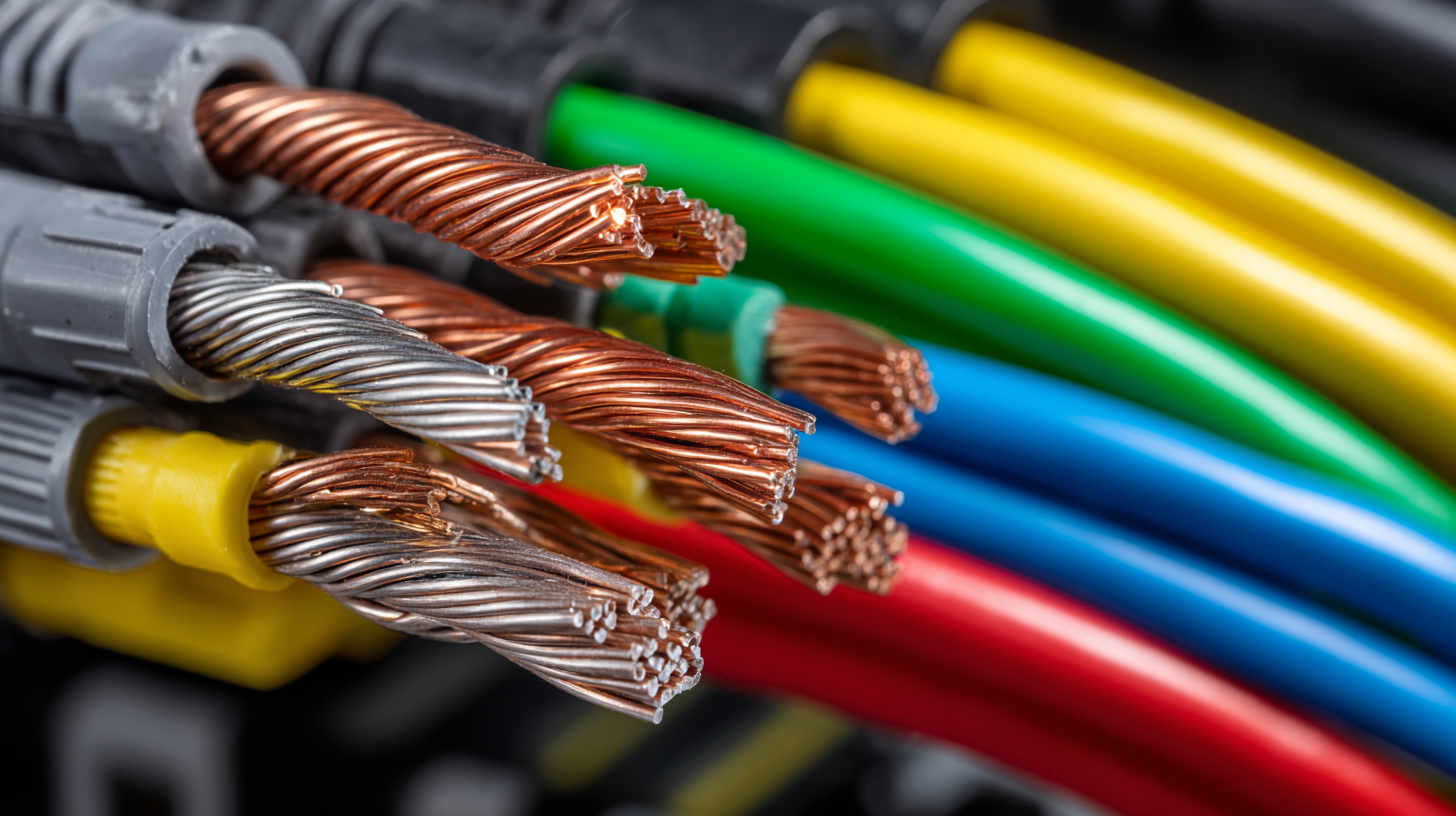

Assessing Wire Cable Material Choices: Copper vs. Aluminum

When it comes to wire cable in modern electrical systems, choosing the right material can significantly impact performance and efficiency. Two of the most common options are copper and aluminum.

Copper wire is known for its superior conductivity, making it a trusted choice for high-performance applications. Its durability and resistance to corrosion also contribute to a longer lifespan, reducing the need for frequent replacements.

Copper wire is known for its superior conductivity, making it a trusted choice for high-performance applications. Its durability and resistance to corrosion also contribute to a longer lifespan, reducing the need for frequent replacements.

On the other hand, aluminum wire offers a lighter and more cost-effective alternative. Despite having lower conductivity compared to copper, advancements in technology have enhanced its performance, making it suitable for various applications. Additionally, aluminum’s flexibility allows for easier handling and installation, particularly in large-scale projects.

Tips: When selecting wire cables, consider the specific needs of your project. If you're working on installations that require high power transmission, copper may be the better choice. For budget-conscious projects that still demand adequate performance, aluminum can be a viable option. Always consult with a professional to determine which material best suits your needs based on factors like load capacity and environmental conditions.

Impact of Wire Cable Specifications on Energy Efficiency in Systems

In modern electrical systems, the performance and energy efficiency heavily depend on the specifications of wire cables used.

High-quality wire cables with appropriate gauge and insulation are crucial in minimizing energy loss.

For instance, a well-sized conductor can significantly reduce resistive heating, which is a common issue in power transmission.

Thicker cables generally have lower resistance, resulting in less energy wasted as heat and more effective power delivery to end devices.

In modern electrical systems, the performance and energy efficiency heavily depend on the specifications of wire cables used.

High-quality wire cables with appropriate gauge and insulation are crucial in minimizing energy loss.

For instance, a well-sized conductor can significantly reduce resistive heating, which is a common issue in power transmission.

Thicker cables generally have lower resistance, resulting in less energy wasted as heat and more effective power delivery to end devices.

Moreover, the choice of materials in wire cables influences not only the longevity of the system but also its overall energy efficiency. Conductors made from copper or aluminum, for example, have different conductivity properties and, therefore, varying efficiencies in energy transmission. Additionally, insulation types play a vital role, as they can affect the thermal properties of cables. Using cables with high thermal resistance can prevent overheating and increase safety, ultimately enhancing system performance while optimizing energy consumption. Thus, understanding wire cable specifications is essential for engineers and designers aiming to create energy-efficient electrical systems.

Understanding the Cost-Benefit Analysis of High-Quality Wire Cables

In modern electrical systems, the choice of wire cable plays a crucial role in determining both performance and safety. A cost-benefit analysis reveals that investing in high-quality wire cables can lead to significant long-term savings. According to the National Electrical Manufacturers Association (NEMA), using premium wire materials can reduce the risk of electrical failures by up to 20%, which in turn can save businesses thousands in downtime and repair costs.

Choosing the right wire cable is not just about initial costs; it’s also about efficiency and lifespan. For instance, superior insulation materials can withstand heat and corrosion better, resulting in a 30% longer service life compared to standard cables. Tips for budget-conscious buyers include considering the total cost of ownership rather than just the upfront price. Evaluate the potential energy savings and maintenance costs over the cable's lifetime.

Moreover, when selecting wire cables, always ensure they comply with relevant industry standards such as the National Electrical Code (NEC). This not only guarantees safety but can also improve efficiency. Consider consulting with electrical engineers or industry reports to assess the best options for specific applications, ensuring you get the most value for your investment in wire cable technology.

Future Trends in Wire Cable Technology and Their Implications for Electrical Systems

As the demand for advanced electrical systems continues to rise, the future of wire cable technology is poised for significant evolution. Innovations such as smart cables, which integrate sensors and data transmission capabilities, are becoming increasingly relevant. These cables can monitor their own conditions and provide real-time information on performance metrics, enhancing both efficiency and safety in electrical systems. This integration not only minimizes failures but also offers invaluable data for predictive maintenance, which is crucial for minimizing downtime and prolonging the lifespan of electrical infrastructure.

Moreover, advancements in materials are set to revolutionize wire cable production. The emergence of lightweight, high-conductivity materials will lead to cables that are not only easier to install but also more efficient in energy transfer. This shift towards more sustainable options, coupled with the push for environmentally friendly manufacturing processes, highlights the growing responsibility of the electrical industry to reduce its carbon footprint. As electric vehicles and renewable energy sources become more mainstream, the evolution of wire cable technology will be pivotal in supporting the infrastructure required for these innovations.

Related Posts

-

Advantages of Choosing High Quality Electric Cable for Your Projects

-

The Ultimate Guide to Choosing the Right Outdoor Electrical Cable for Your Needs

-

Comprehensive Guide to Selecting the Best Flexible Cable Conduit for Your Project

-

Exploring Innovative Power Extension Cable Options for Every Need

-

Top Strategies for Sourcing Shielded Power Cable in Global Markets

-

10 Essential Tips for Sourcing Electric Cables Effectively in 2023

Products

Products

LEARN MORE

Current Inventory

Current Inventory

LEARN MORE

Custom Solutions

Custom Solutions

WE CAN HELPLighting Power & Control-Signal Cable

This content is restricted to site members. If you are an existing user, please log in. New users may register … LEARN MORE “Lighting Power & Control-Signal Cable”

LOOKING

FOR HELP?

We are here to help. You can contact us or create an account online to have access to special products, technical specifications and our new online quote tool.

ELECTRO CABLES

9 Riverside Drive

P.O. Box 276

Trenton, Ontario

CANADA K8V 5R5

N.A. Toll Free: 888-ELECTRO

(1-888-353-2876)

World: 613-394-4896

Fax: 613-394-4101

Email: sale@machinecables.com

We manufacture cables that are certified by the Canadian Standards Association (CSA), listed by Underwriters Laboratories and/or listed by Intertek (ETL).

Our quality management system is registered to ISO 9001: 2015. Our team is dedicated to consistently providing quality service and products to our customers.

© 2025 ELECTRO CABLES • SITE BY SNAP 360•