A partner you can trust

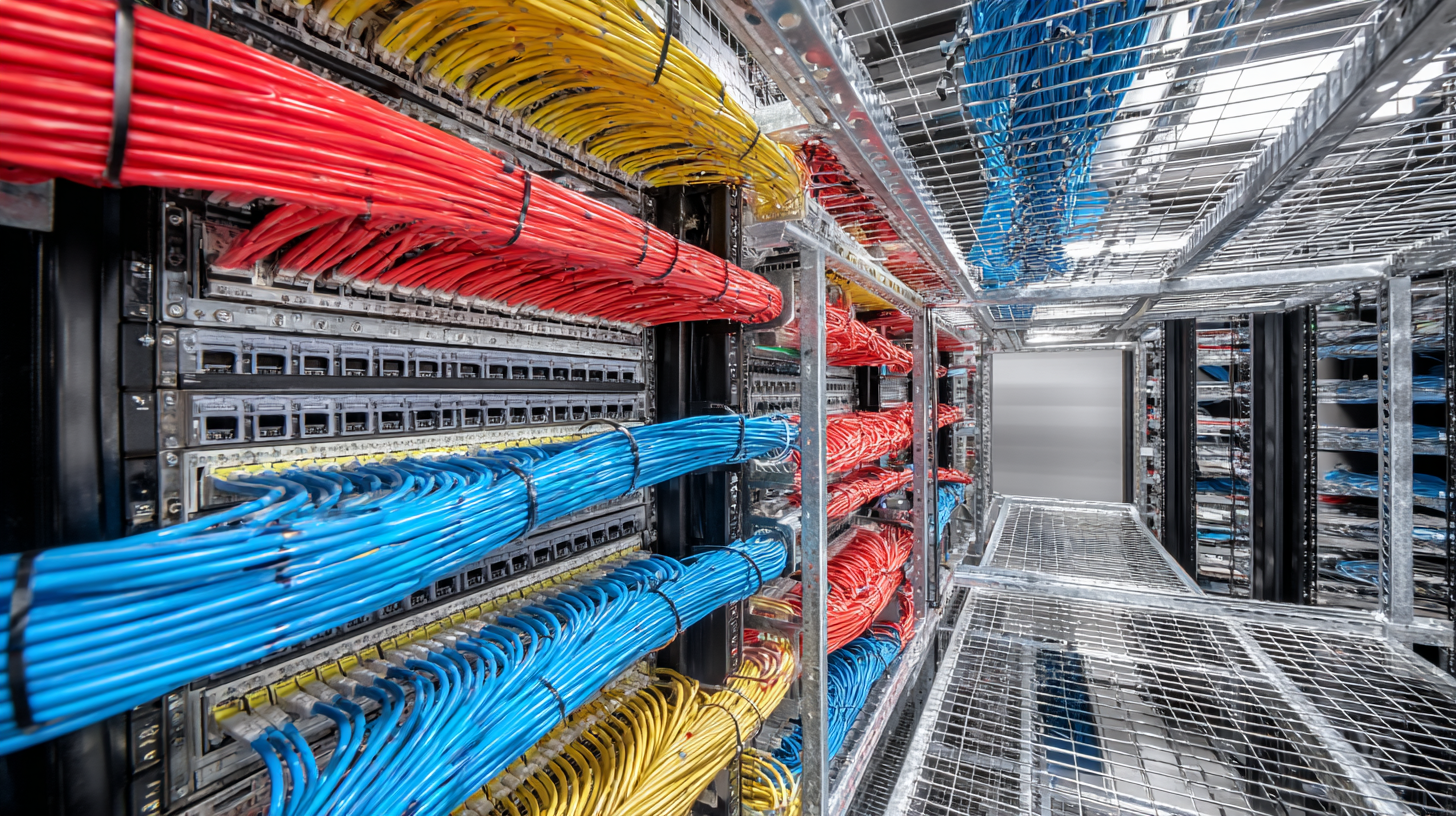

7 Best Practices for Using Wire Mesh Cable Tray in Modern Data Centers

In the rapidly evolving landscape of modern data centers, the efficient management of cabling infrastructure is critical to ensuring optimal performance and reliability. The adoption of wire mesh cable tray systems has emerged as a best practice among industry leaders, addressing the increasing demands for organization, airflow efficiency, and cable protection in high-density environments. According to a recent report by MarketsandMarkets, the global cable tray market is anticipated to reach USD 7.8 billion by 2025, with wire mesh cable trays being a significant contributor to this growth due to their versatility and ease of installation. These systems facilitate better heat dissipation, reduce clutter, and streamline maintenance efforts, thus enabling data center operators to improve uptime and scalability. As we explore the seven best practices for utilizing wire mesh cable trays effectively, it becomes evident that they play a pivotal role in enhancing the operational efficiency of contemporary data centers.

Understanding Wire Mesh Cable Tray: An Overview of Types and Features

Wire mesh cable trays have become increasingly important in modern data centers, providing effective solutions for cable management while ensuring safety and accessibility. These trays are typically constructed from steel or aluminum, offering a robust framework that supports both power and data cabling. According to the Data Center Infrastructure Management (DCIM) Market Analysis report by Research and Markets, the adoption of wire mesh solutions can reduce installation costs by 30% compared to traditional cable management systems. The open design promotes airflow, making them an ideal choice for environments where thermal management is crucial.

There are various types of wire mesh cable trays, each catering to different installation needs. For instance, ladder trays, which resemble a ladder structure, are optimal for larger volumes of cables, particularly in high-capacity facilities. In contrast, solid-bottom trays provide additional support for more sensitive cables that may require extra protection against physical damage. A recent study from MarketsandMarkets indicates that the global cable tray market is set to grow by 8.3% annually, underscoring the increasing reliance on efficient cable management systems in data centers. The flexibility and versatility offered by wire mesh cable trays position them as a crucial component in the drive toward more efficient and organized data center operations.

Benefits of Using Wire Mesh Cable Tray in Data Center Infrastructure

Wire mesh cable trays have become increasingly popular in modern data centers for several compelling reasons. One of the primary benefits is their ability to enhance airflow around the cables. Unlike solid trays, wire mesh allows for better ventilation, which is crucial in preventing overheating and ensuring optimal performance of sensitive equipment. This increased airflow helps in maintaining an efficient thermal environment, reducing the risk of downtime due to heat-related issues.

Additionally, wire mesh cable trays are typically easier to install and adjust compared to other cable management solutions. Their lightweight design simplifies handling during installation, making it more feasible to adapt to the ever-evolving infrastructure needs of a data center. This flexibility enables data center operators to quickly reconfigure their setups as technology and demands change, facilitating seamless upgrades and expansions. Ultimately, these advantages contribute to a more efficient, safe, and organized data center environment.

Best Practices for Installation and Maintenance of Wire Mesh Cable Trays

When it comes to the installation and maintenance of wire mesh cable trays in modern data centers, adhering to best practices is crucial for ensuring efficiency and safety. According to a report by MarketsandMarkets, the global cable management system market, which includes wire mesh cable trays, is projected to reach USD 33.45 billion by 2025. Proper installation techniques can enhance the longevity and reliability of these systems, significantly reducing downtime caused by cable management issues.

One key practice is to ensure that the trays are correctly sized based on the anticipated cable load; the National Electrical Manufacturers Association (NEMA) recommends that the tray fill be no more than 50% of the tray’s capacity for optimal air circulation and heat dissipation. Regular inspections and maintenance are also paramount. By adhering to a maintenance schedule that includes periodic cleaning and checking for wear and tear, data centers can minimize the risk of overheating and ensure that cables remain organized and accessible. This proactive approach not only prolongs the lifespan of the cable trays but also contributes to the overall efficiency of the data center infrastructure, aligning with industry standards.

Comparative Analysis: Wire Mesh Cable Trays vs. Solid Bottom Trays

In the ever-evolving landscape of modern data centers, the choice between

wire mesh cable trays and

solid bottom trays has significant implications

for infrastructure design and efficiency.

Wire mesh trays offer

exceptional ventilation properties, which are crucial for maintaining optimal temperatures

in high-density environments. According to the

"Data Center Cooling Trends Report" published by the

International Data Corporation (IDC), data centers utilizing wire mesh trays

can experience a reduction in cooling energy costs by up to

30%, as these trays facilitate better airflow,

thereby minimizing hotspots.

On the other hand, solid bottom trays provide a more rigid structure,

which is beneficial for protecting sensitive cabling from external damage and contamination.

However, they can hinder airflow, leading to potential overheating issues. A study from the

Uptime Institute revealed that data centers relying heavily on

solid bottom systems reported a 20% increase in energy consumption

associated with cooling compared to those using wire mesh alternatives.

Ultimately, while both options have their distinct advantages, wire mesh trays are increasingly

preferred in modern data centers due to their support for

energy efficiency

and thermal management.

Future Trends in Wire Mesh Cable Tray Design and Technology for Data Centers

In the rapidly evolving landscape of data centers, the design and technology of wire mesh cable trays are experiencing significant advancements. According to recent industry reports, the global data center market is projected to grow at a compound annual growth rate (CAGR) of 10.7%, reaching an estimate of $500 billion by 2026. This expansion necessitates solutions that ensure both efficiency and adaptability, where wire mesh cable trays play a crucial role. Their lightweight yet durable structure not only promotes optimal airflow but also facilitates easier access for maintenance and upgrades, aligning with the modern demands of energy efficiency and sustainability.

Looking ahead, several trends are poised to shape the future of wire mesh cable tray systems in data centers. Emerging technologies such as the Internet of Things (IoT) and artificial intelligence (AI) are leading to smarter designs that integrate real-time monitoring capabilities. For instance, a report from MarketsandMarkets notes that intelligent cable management solutions could reduce installation times by up to 30%, thereby minimizing operational downtime. Furthermore, as more data centers strive for green certifications, wire mesh trays made from recyclable materials are becoming increasingly popular, reflecting a shift towards eco-friendly practices in data management infrastructure.

Related Posts

-

The Future of Underground Cable Conduit: Innovations Shaping Tomorrow's Infrastructure

-

The Ultimate Guide to Choosing the Right Outdoor Electrical Cable for Your Needs

-

The Ultimate Guide to Choosing the Right Electric Cable for Your Projects

-

Exploring Innovative Power Extension Cable Options for Every Need

-

How to Choose the Best Multi Cable Charger for Your Devices: Key Features and Expert Insights

-

What is the Importance of Wire Cable in Modern Electrical Systems

Products

Products

LEARN MORE

Current Inventory

Current Inventory

LEARN MORE

Custom Solutions

Custom Solutions

WE CAN HELPLighting Power & Control-Signal Cable

This content is restricted to site members. If you are an existing user, please log in. New users may register … LEARN MORE “Lighting Power & Control-Signal Cable”

LOOKING

FOR HELP?

We are here to help. You can contact us or create an account online to have access to special products, technical specifications and our new online quote tool.

ELECTRO CABLES

9 Riverside Drive

P.O. Box 276

Trenton, Ontario

CANADA K8V 5R5

N.A. Toll Free: 888-ELECTRO

(1-888-353-2876)

World: 613-394-4896

Fax: 613-394-4101

Email: sale@machinecables.com

We manufacture cables that are certified by the Canadian Standards Association (CSA), listed by Underwriters Laboratories and/or listed by Intertek (ETL).

Our quality management system is registered to ISO 9001: 2015. Our team is dedicated to consistently providing quality service and products to our customers.

© 2025 ELECTRO CABLES • SITE BY SNAP 360•